WP6: Demonstrator Tooling

- Tooling Requirements

- Tooling Concepts

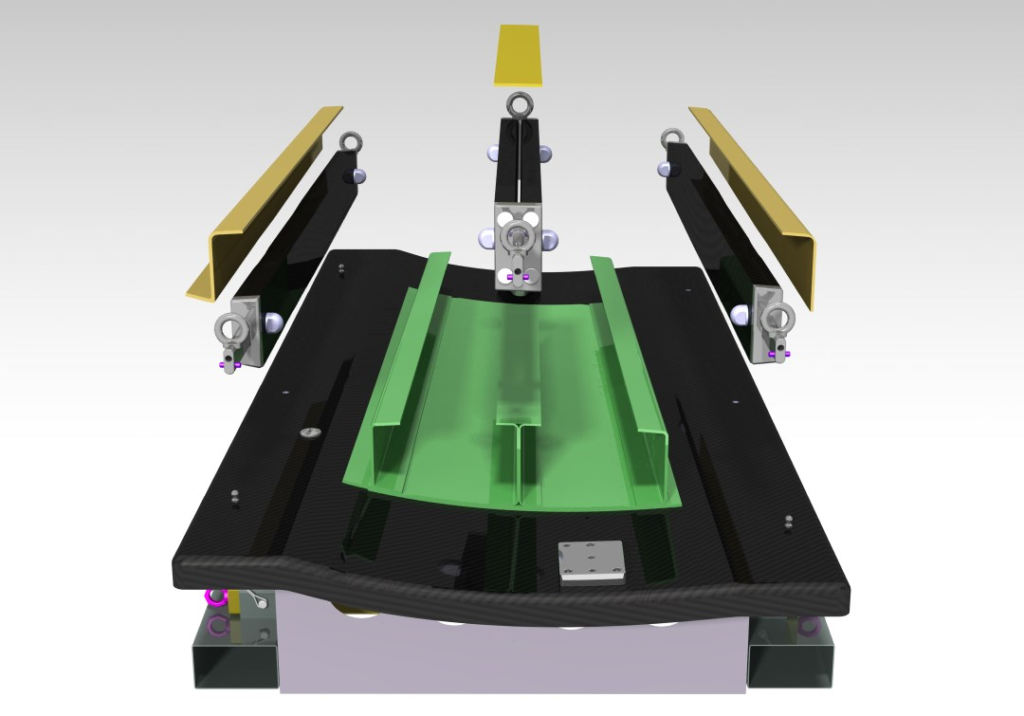

- Tool design

- Tool Manufacture

Design and manufacture innovative tooling which Will allow integral manufacture of 3 spars and skin of a 7 meter wing structure

Should be suitable for both Liquid Resin Infusion and prepreg manufacturing

Should allow minor adjustments to compensate for “spring-in” deformation effects

Will have an overall cost reduction in comparison with similar metallic tooling

Develop, design and manufacture an innovative bonding assembly tooling, in order to obtain a high quality airworthy structural bond between a lower wing cover to the already assembled wing substructure

Ensure uniform pressure over multiple 7M bond-line

Ensure uniform thickness over multiple 7M bond-lines