Technology

OPTICOMS LEADING TECHNOLOGIES

- Innovative "working skin" design

- Integral structure manufacture

- Automated manufacturing trade-off

- Infusion of 7 m integral structure

- Large scale structural bonding

- SHM algorithm for bond line damage

- Novel assembly tooling

- Virtual testing

- Out of autoclave

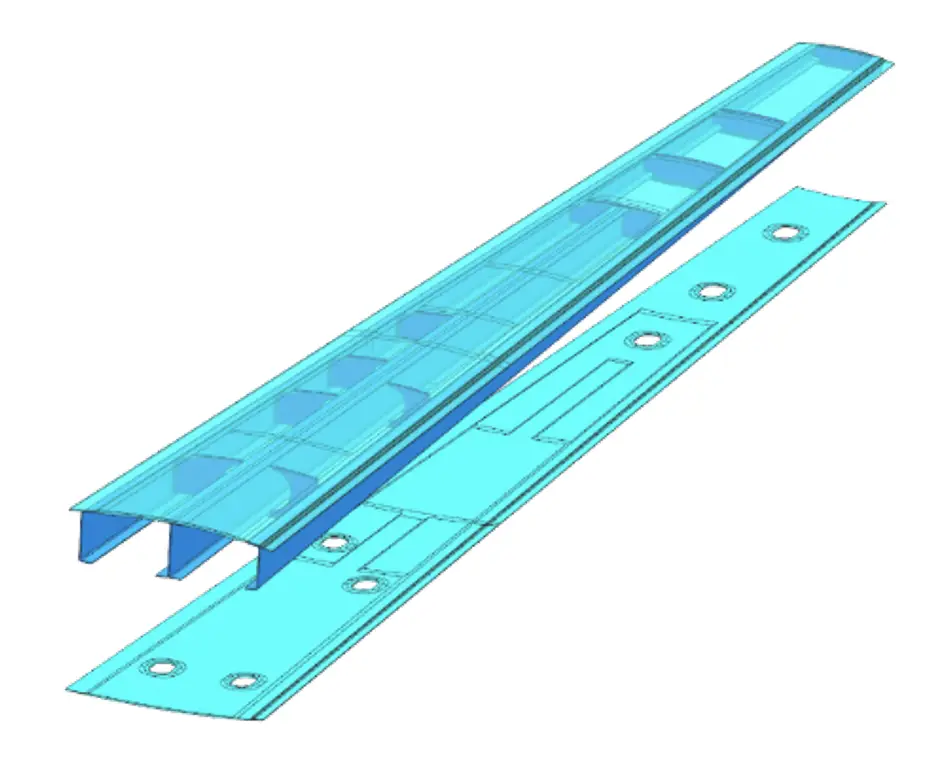

Innovative "working skin" design

- Solid Laminate UD working skin

- Allows simple flat spars (HDF)

- Integral structure (skin and spars)

- Multi-spar structures

- Design for automation

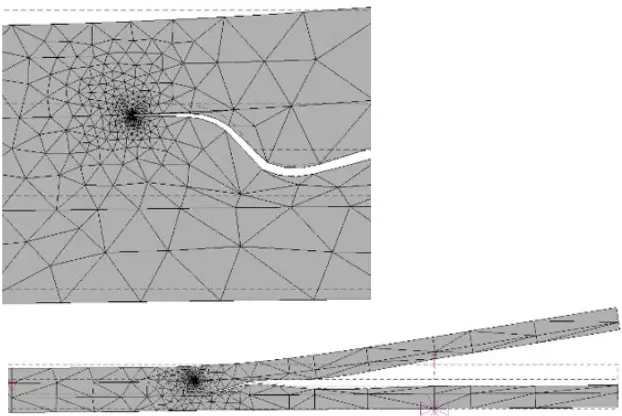

Integral structure manufacture

No dry spots, no leakage, no damage from tool extraction

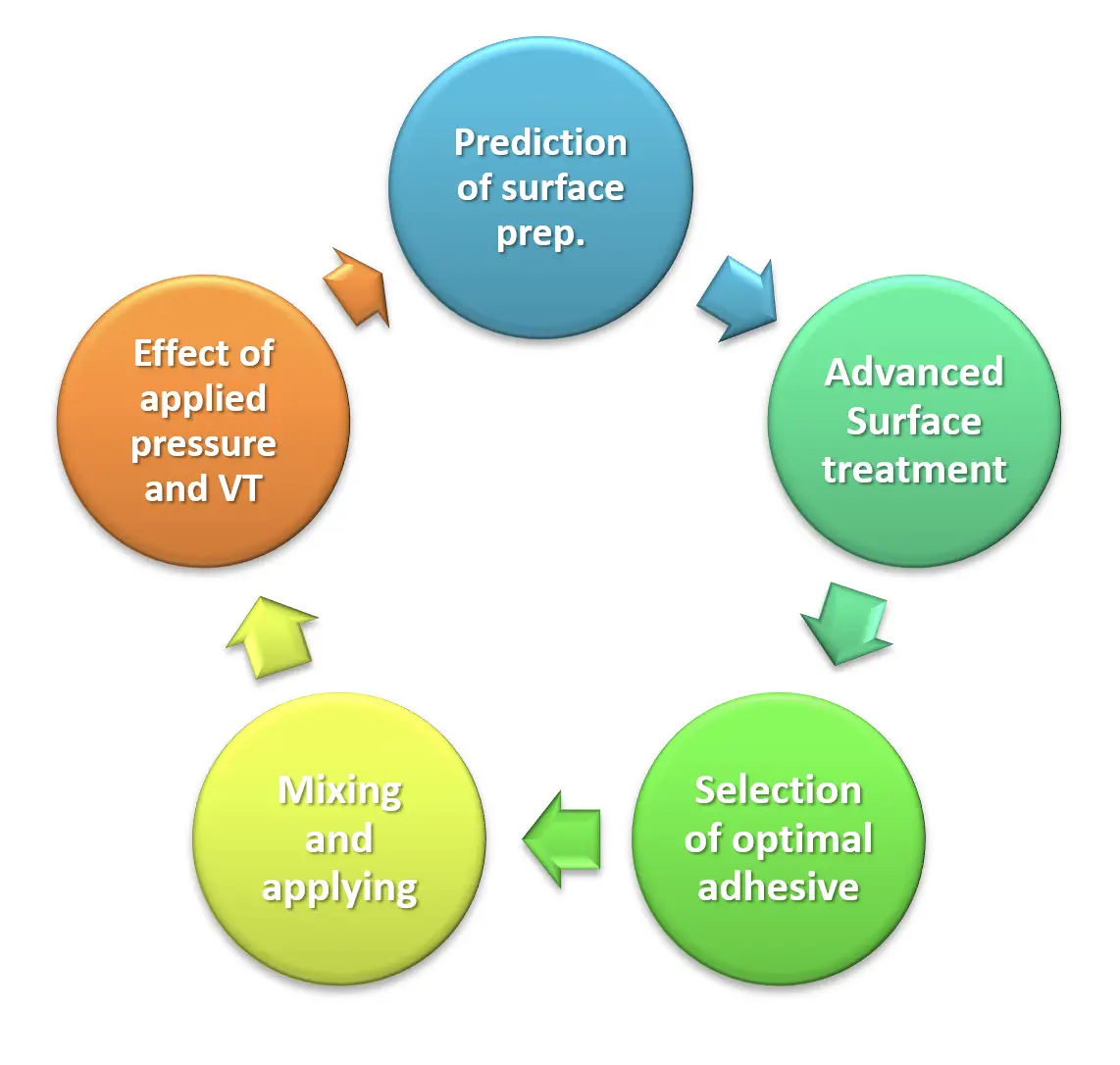

Large scale structural bonding

Structural Bonding:

Dividing the adhesive bonding process to well defined, critical steps allows:

- Process control

- Quantification of process parameters

- Repeatability

- Identification of root causes in case of failure

Novel assembly tooling

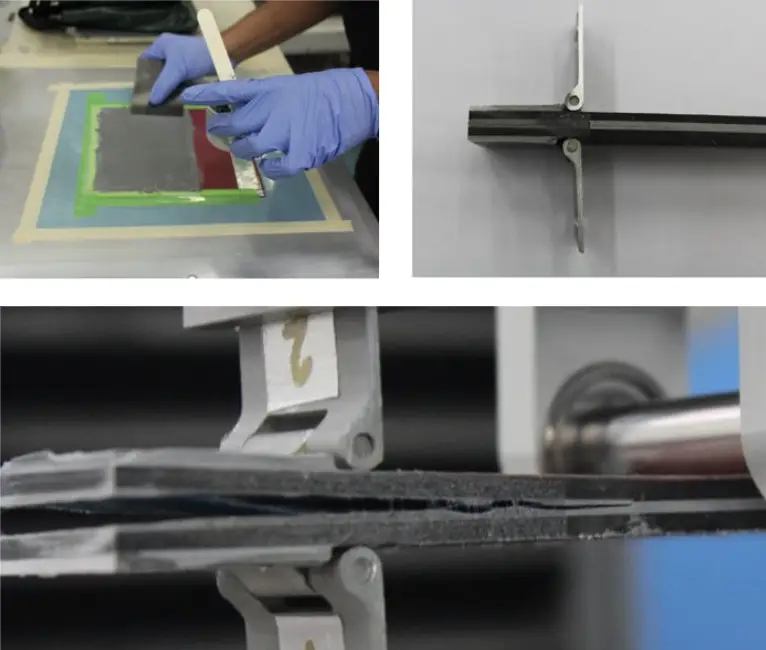

Virtual testing

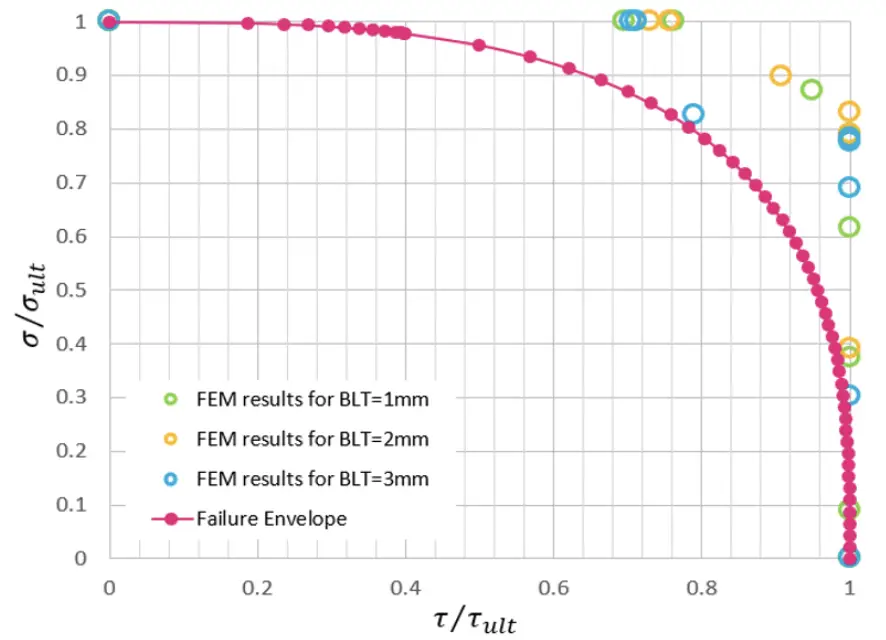

105 test specimens were fabricated and tested

Finite element modeling of the stress field around debond

Failure criteria and failure prediction envelopes established

Significant saving on further qualification testing for the project – substantial design phase cost saving

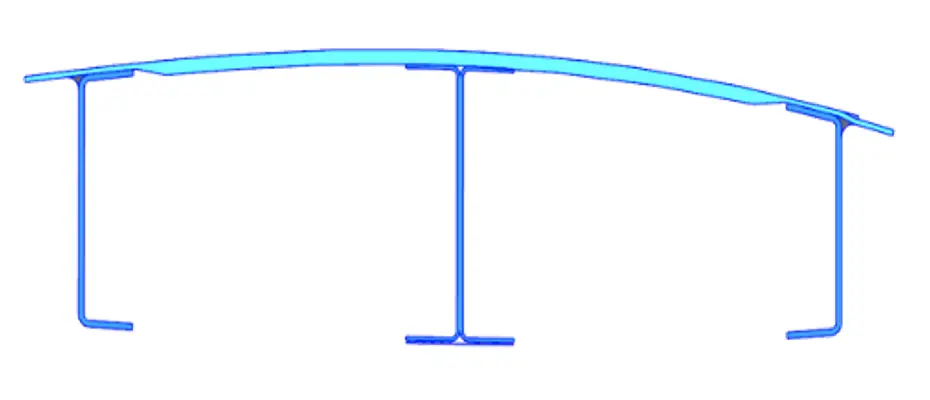

CFP FITCOW WING BOX NOVEL MANUFACTURING TOOLING

Consist of consortium of partners:

- INCAS - National institute for Aerospace research (co-ordinator)

- Tekno compositi - Composite tooling manufacturer

- Romaero S.A. - Romania Aerospace industry

- Project starting date: 1.2.19

CfP WING BOX BONDING

Project objective - to develop, design and manufacture the required full scale innovative bonding assembly tooling, in order to obtain a high quality airworthy structural bond between a lower wing cover to the already assembled wing substructure

- O.M.P.M and Metitalia: Design and manufacturing companies of aerospace structural parts and tooling.

- Protom Group S.p.A.: an Engineering Solutions provider

- LAER: Design, Manufacturing , Assembling and Integration of Complex Aerospace Structures assemblies

- Marotta S.r.l: is specialized in the manufacturing of high precision mechanical components for aeronautics, military and space applications